[Focus on Ceramic sector] Cooling and Energy saving, you can!

Cooling and Energy Saving,

with GreenBlow® is possible !!!

The digital tile printing process, in order to be effective, needs two fundamental conditions:

– receive the tile at a temperature compatible with the printer;

– absence of surface steam which could damage the print heads.

For these reasons, the cooling process of the tiles before the digital printer is essential to obtain an optimal printing result, limit production waste but also preserve the expensive print heads.

Is it possible to cool and limit energy consumption ?

With the components of our GreenBlow® Air Line it is possible to create battery cooling systems with a low energy impact thanks to the use of high-performance and low-consumption motors.![]()

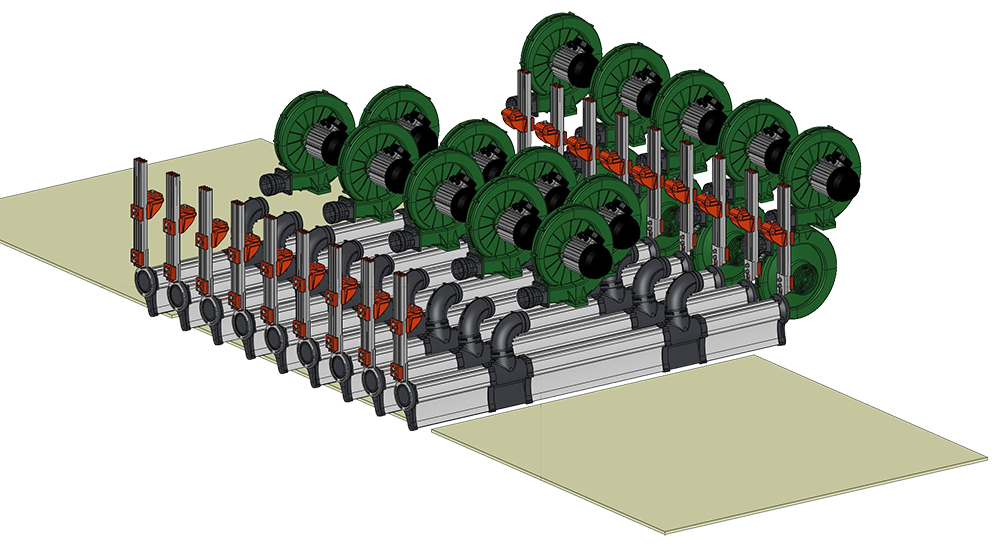

The blowers used for the cooling process are GreenBlow IE3, equipped with a high efficiency 0.37kW 50Hz electric motor, built to our specifications. This motor, if combined with an inverter, can operate up to 65Hz without dropping of torque making it adaptable to environmental conditions.

Therefore, in the event of lower ambient temperatures, it is possible to optimize the operation of the blower in order to increase energy savings (the programmed inverter, supplied by us, already includes this function which can be activated).

A cooling battery made up of about 10 GB IE3 at 65 Hz with relative air knives can consume a maximum of 4,8Kw !!!

How does cooling through blowers work?

The GreenBlow® blowers system uses air at room temperature, it does not create a thermal shock but a turbulence on the tile surface which both cools the surface and interrupts the evaporation process of the glaze – or of the engobe.

This phenomenon has sufficient persistence to overcome the passage under the print heads, optimizing printing and preserving the heads.

What do I need to create a cooling system?

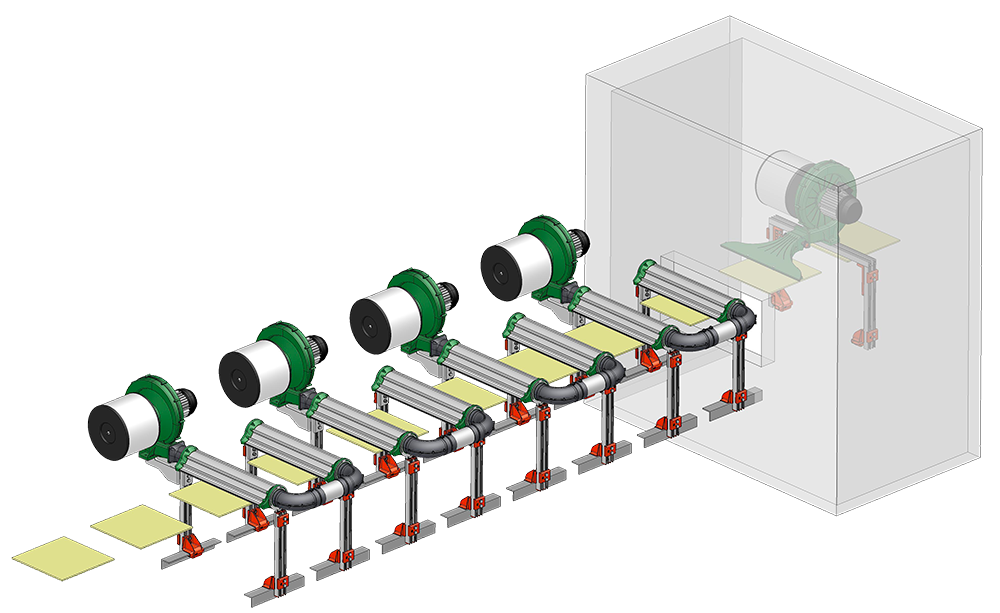

The GreenBlow® catalog includes all the necessary components: blowers, diffusers and air knives, together with connectors and supports that allow you to quickly and easily create your own cooling combination that can be adapted to your production line and production needs.

Contact your sales representative to be able to understand together which components of the line are necessary to best configure your application.

Possible system configurations

Thanks to the wide range of components available, it is possible to “tailor-made” the cooling system to your needs.

The configurations can be many: very compact systems with reduced dimensions, modular systems that can operate at full capacity or reduced depending on the temperatures, systems integrated with other cooling stations depending on the type of production in progress, fixed or trailerable systems, etc. …

Finally, to complete the system, it is also possible to integrate a suction station to intercept deposits of dust and eliminate them both from the tile and from the work environment (even in the absence of suction centralized system).

Maintenance costs ?

This system has practically zero maintenance costs.

Furthermore, if a blower stops, the cooling system does not stop, so production can continue at the same speed with minimal loss of efficiency.

Replacement is very quick and can be done by any maintenance worker without waiting for the specialized technician.

HERE it’s possible to see other GreenBlow Ceramic Sector applications