P.IVA: IT 00271100356 | REA: RE-124067 | C.S. € 46.800 I.V. – Privacy – Cookie Policy

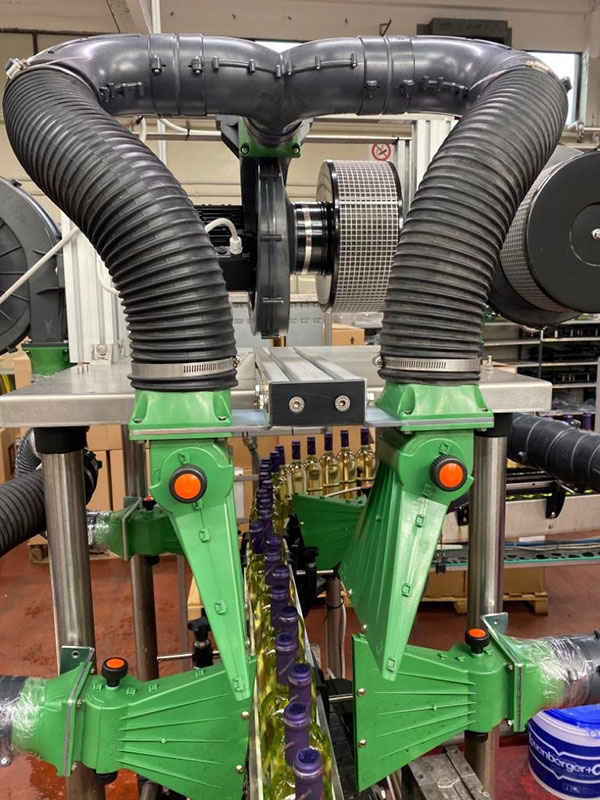

Effective bottle drying

Sector: Food, Beverage

Application: Drying

GB type: GB IE3, GB Plus

Application features:

Removal of water from the neck under the cap and moisture from the body of the bottle.

Variable speeds according to industrialization and volumes, from 1’000 bottles / hour up to 50’000 bottles / hour.

Targets:

Avoid the formation of rust under the crown cap and be able to apply both adhesive labels and water-based glue labels effectively and durably.

Energy consumption:

Compared to the currently used systems, power consumption can reduce up to 1/10 in comparison with compressed air and up to 1/5 in comparison with other electric fans. In general, competing systems include closed stations containing air blades or batteries of nozzles, powered by compressors and / or fans with 7.5-15 kw electric motors. And, above all, limited or absent flexibility because parts of a dedicated transport line are required.

Notes on the results obtained:

Reduced size and greater mounting flexibility, allow the GREEN BLOW system to be applied even in transit areas.

In the attached images different types of diffusers have been used. These could change according to the speed of the line and the required drying requirement.